Areas of application and case studies

SOLUTIONS

Advanced Static VAR Generator

ASVG (Advanced Static VAR Generator)

Areas of application

- Industrial manufacturing plants: Compensation for rapid load changes and maintenance of power factor.

- Data Centers: Ensure a stable power supply for critical IT equipment.

- Renewable energy integration: Reactive energy management in wind and solar farms.

- Commercial buildings: Improving power factor and reducing energy costs.

Case Studies

- Industrial manufacturing plants: In a steel mill, ASVGs help stabilize voltage during operation of electric arc furnaces, which can cause significant voltage fluctuations.

- Data Centers: ASVGs are used to maintain voltage stability and improve power quality, thereby protecting servers and storage devices from voltage sags and surges.

- Renewable Energy Integration: ASVGs are deployed in solar power plants to compensate for the intermittent nature of solar power, ensuring stable voltage output.

- Commercial buildings: In large office complexes, ASVGs help maintain a high power factor, reducing utility demand charges and improving energy efficiency.

Tailor-made solutions

ASVG Advanced Static VAR Generator

ASVG Advanced Static VAR Generator

ASVG Advanced Static VAR Generator

ASVG Advanced Static VAR Generator

ASVG Advanced Static VAR Generator

ASVG Advanced Static VAR Generator

ASVG Advanced Static VAR Generator

ASVG Advanced Static VAR Generator

ASVG Advanced Static VAR Generator

ASVG Advanced Static VAR Generator

ASVG Advanced Static VAR Generator

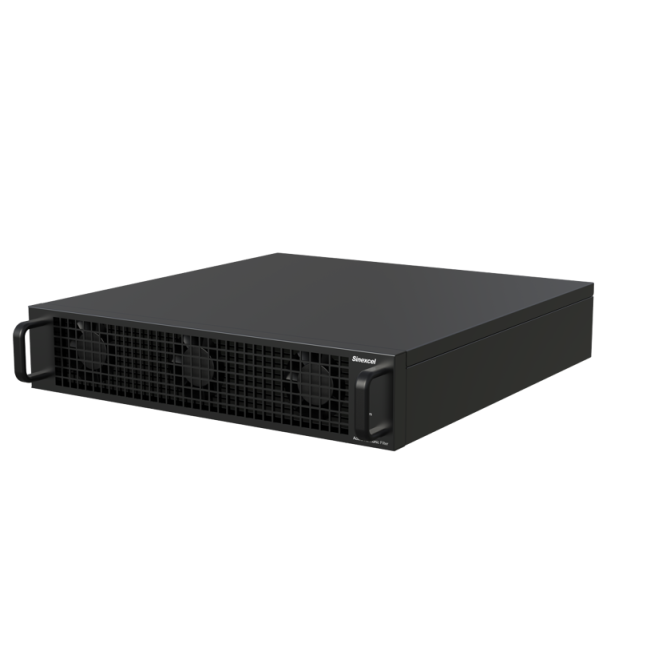

Active Harmonic Filter

AHF (Active Harmonic Filter)

Areas of application

- Industrial Automation: Mitigate harmonics generated by variable frequency drives (VFD) and other non-linear loads.

- Hospitals: Protection of sensitive medical equipment from harmonic distortions.

- Commercial Buildings: Maintaining power quality in buildings with significant electronic loads.

- Data Centers: Ensuring a clean power supply for servers and IT infrastructure.

Case Studies

- Industrial Automation: In a semiconductor manufacturing plant, AHFs are used to reduce harmonics from VFDs, ensuring the smooth operation of sensitive production equipment.

- Hospitals: AHFs are installed to mitigate harmonics caused by imaging devices and other electronic medical equipment, ensuring reliable operation and reducing interference.

- Commercial Buildings: AHFs in a shopping center help mitigate harmonics from lighting systems, HVAC units, and escalators, improving overall power quality.

- Data Centers: AHFs are used to filter harmonics generated by UPS systems and other electronic loads, protecting data center operations from power quality issues.

Tailor-made solutions

AHF Active Harmonic Filter

AHF Active Harmonic Filter

AHF Active Harmonic Filter

AHF Active Harmonic Filter

AHF Active Harmonic Filter

AHF Active Harmonic Filter

AHF Active Harmonic Filter

AHF Active Harmonic Filter

AHF Active Harmonic Filter

Dynamic Voltage Restorer

DVR (Dynamic Voltage Restorer)

Areas of application

- Industrial manufacturing: Protection of sensitive equipment against voltage drops and interruptions.

- Commercial Buildings: Ensure a stable power supply for critical operations.

- Utility distribution networks: Improving energy quality for end consumers.

- Airports: Maintaining power quality for critical airport operations.

Case Studies

- Industrial manufacturing: In an automotive manufacturing plant, DVRs are used to protect robotic assembly lines from voltage drops caused by large motor starts.

- Commercial Buildings: DVRs in a financial data processing center ensure that sensitive data processing equipment operates without interruption during power outages.

- Utility Distribution Networks: Utility companies deploy DVRs on distribution networks to protect residential and commercial customers from voltage sags and surges.

- Airports: DVRs are used to ensure stable power for air traffic control systems, runway lighting and baggage handling systems, improving operational reliability.

Active Voltage Conditioner

AVC (Active Voltage Conditioner)

Areas of application

- Industrial Plants: Protection of production lines against voltage surges and drops.

- Telecommunications: Voltage stabilization for telecommunications equipment.

- Renewable energy systems: Stabilization of output voltage from renewable energy sources.

- Data Centers: Provide voltage regulation for critical IT infrastructure.

Case Studies

- Industrial Plants: In a pharmaceutical manufacturing facility, AVCs ensure a stable voltage supply to critical production equipment, preventing downtime and product loss.

- Telecommunications: AVCs are used in telecommunications base stations to maintain stable voltage levels, ensuring reliable communication services.

- Renewable energy systems: In a wind farm, AVCs help compensate for voltage variations caused by changes in wind speed, ensuring a constant supply of energy to the grid.

- Data Centers: AVCs in a data center help maintain stable voltage levels, protecting servers and network equipment from voltage fluctuations.

Tailor-made solutions

AVC Active Voltage Conditioner

AVC Active Voltage Conditioner

AVC Active Voltage Conditioner

AVC Active Voltage Conditioner

Technical support

Our technical support covers pre-sales and after-sales & warranty needs.

Pre-sale support:

Our group of local specialists are entirely available to our clients to advise them on all types of queries.

At Effisine we have the direct support of the technical groups of the manufacturers to ensure that from the conception of each solution to the selection of equipment to make it up, they are entirely in accordance with the quality, safety and efficiency requirements of the highest international standards in energy efficiency.

After-sales support & warranty:

We continue to provide permanent local and remote specialized support during the exploitation phase of the products we provide to offer the fastest response times to any query.

We provide direct manufacturer’s warranty locally for the products we sell and, to the extent possible, we repair the products locally to reduce the time and cost of the same.